How to Prevent Corrosion of Cryogenic Liquid Tank?

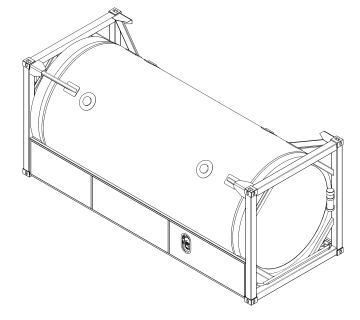

A pressure vessel is a closed device that holds a gas or liquid and carries a certain pressure. Pressure vessels are used in a wide range of applications and have important positions and functions in many sectors, such as industrial and civil. However, a common problem with pressure vessels in use is corrosion.

Corrosion, cracking, damage, erosion, and physical damage are all obvious failure modes of Cryogenic Liquid Tank. Therefore, be careful when using pressure vessels. Cryogenic Tank Supplier believes that there are two reasons for the corrosion of pressure vessels.

Material characteristics:

The material characteristics of the pressure vessel affect and determine the level of corrosion resistance of the pressure vessel. The corrosion rate will be disturbed by the structural density and oxidizing property of the surface metal crystal. The larger the crystal structure density, the rougher the surface, the larger the crystal pores, the easier the service material will penetrate, and the more likely the corrosion reaction will occur.

External environment:

The internal and external environment of Cryogenic Liquid Tank will directly affect its anti-corrosion performance. Pressure vessels carry a large number of reagents, and the cost of the materials contained therein is high. It is inevitable that a small number of corrosive materials, such as acidic materials and alkaline materials, may be mixed, and these components are likely to cause corrosion of the pressure vessel.

Causes of Corrosion in Cryogenic Tanks

- Material Characteristics

The material of the cryogenic liquid tank determines its corrosion resistance. Tanks made from high-grade stainless steel or specially treated alloys are more resistant, while rough or porous surfaces are more susceptible.

- Dense crystal structures: Reduce penetration of corrosive substances.

- Smooth surfaces: Minimise corrosion initiation points.

- Surface treatments: Protective coatings or passivation can further enhance resistance.

- Environmental Factors

The internal and external environment of the tank has a direct impact on corrosion:

- Chemical residues: Acidic or alkaline substances left inside the tank can trigger corrosion.

- Moisture exposure: Condensation or damp storage conditions increase risk.

- Temperature fluctuations: Can cause micro-cracks in coatings, exposing metal to corrosive agents.

Practical Tips to Prevent Corrosion

- Choose the Right Materials: Use tanks made of stainless steel or corrosion-resistant alloys for maximum durability.

- Apply Protective Coatings: Anti-corrosion coatings or surface passivation treatments enhance long-term resistance.

- Regular Inspection and Maintenance: Schedule routine checks for cracks, pitting, and surface damage.

- Proper Cleaning: Remove any acidic, alkaline, or reactive chemical residues after use.

- Controlled Storage Environment: Keep tanks in dry, ventilated areas to minimise moisture exposure.

- Monitor Internal Pressure and Conditions: Avoid prolonged exposure to reactive gases without proper safety measures.

By implementing these preventive measures, operators can extend the lifespan of cryogenic liquid tanks, ensure safe operation, and reduce the risk of costly downtime.

No comment