ISO11439 Type 2 CNG Cylinder – supplier

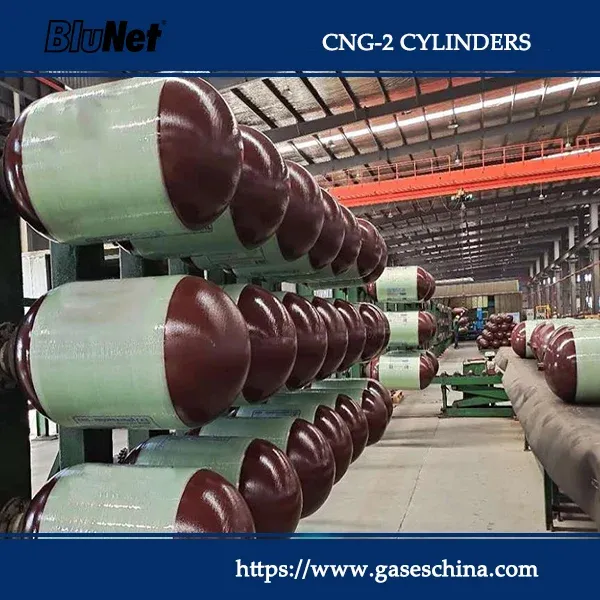

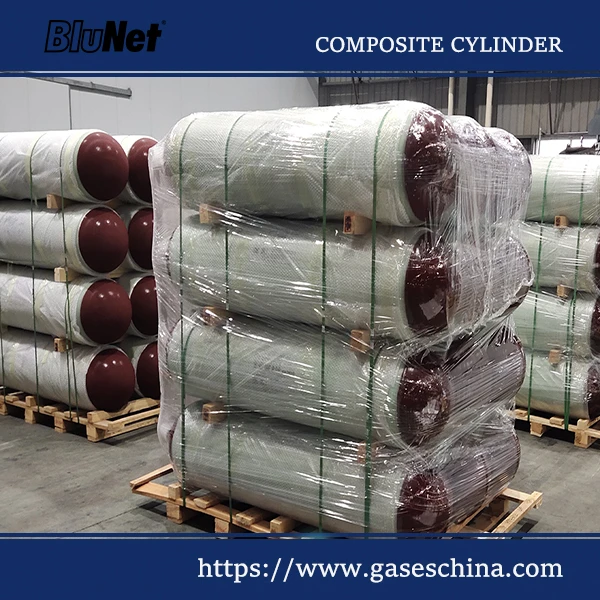

Type 2 CNG cylinders are composite gas cylinders with steel or aluminium lining and a barrel reinforced with long fibres impregnated with “hoop winding” resin.

CNG composite Cylinder with steel liners (hoop-wrapped) for Vehicles manufactured by our company fulfill the design and manufacturing requirements of ISO11439:2000

High-pressure cylinders, known as gas cylinders, are utilized for onboard natural gas storage in automotive vehicles.

DSW products are designed for buses, cars, and various Natural Gas vehicle applications with good low-temperature toughness, fatigue resistance, low weight, high safety, etc.

Technical parameters of CNG-wrapped cylinders for the Vehicle |

|||||||

| Standard: GB/T24160, ISO11439:2013 R110 | |||||||

|

Product No. |

Internal OD |

Volume |

Length |

Weight |

Wall thickness |

Working Pressure |

Material |

|

CNG2-G-325-45-20B |

ø325(Internal) ø334(External) |

45 |

735 |

36 |

4.6 |

20 |

30CrMo |

|

CNG2-G-325-50-20B |

50 |

792 |

40 |

||||

|

CNG2-G-325-55-20B |

55 |

857 |

42 |

||||

|

CNG2-G-325-60-20B |

60 |

921 |

46 |

||||

|

CNG2-G-325-65-20B |

65 |

985 |

50 |

||||

|

CNG2-G-325-70-20B |

70 |

1049 |

52 |

||||

|

CNG2-G-325-75-20B |

75 |

1113 |

55 |

||||

|

CNG2-G-325-80-20B |

80 |

1178 |

59 |

||||

|

CNG2-G-325-85-20B |

85 |

1243 |

61 |

||||

|

CNG2-G-325-90-20B |

90 |

1306 |

67 |

||||

|

CNG2-G-325-100-20B |

100 |

1434 |

71 |

||||

|

CNG2-G-325-110-20B |

110 |

1563 |

78 |

||||

|

CNG2-G-325-120-20B |

120 |

1691 |

85 |

||||

Manufacturing Process

The Type 2 CNG Cylinder, made from a 4130X seamless steel tube, can store natural gas at a pressure of either 20 MPa or 25 MPa.

This seamless steel tube has ISO 9809-1/ISO 9809-3/EN/DOT approval. We classify it as an explosive pressure vessel that holds flammable and explosive gases.

The storage pressure for automotive cylinders is 20 MPa. There are four categories of CNG gas cylinders available. The first category is seamless alloy steel cylinders (CNG-1). CNG-2 is a composite gas cylinder with a steel or aluminium lining and a barrel reinforced with long fibres impregnated with “hoop-winding” resin. The third category consists of composite gas cylinders that have an aluminum liner, along with carbon fibre that is fully wound and glass fibre that is ring wound for reinforcement (CNG-3). The fourth category is the composite gas cylinder with a plastic liner, carbon fibre full winding, and glass fibre ring winding reinforcement (CNG-4). Each compressed gas cylinder has advantages and disadvantages, varying according to the specific application. Steel, typically high-quality chromium-molybdenum, forms the main cylinders used worldwide. Chromium-molybdenum steel and the ISO 11439 and ECE R110 standards can meet the requirements of most countries. A complete automotive CNG composite cylinder includes a cap, a valve, and a safety relief device. The cap protects the valve, and the safety relief device on the valve should be of the rupture disc-fusible plug combination type.