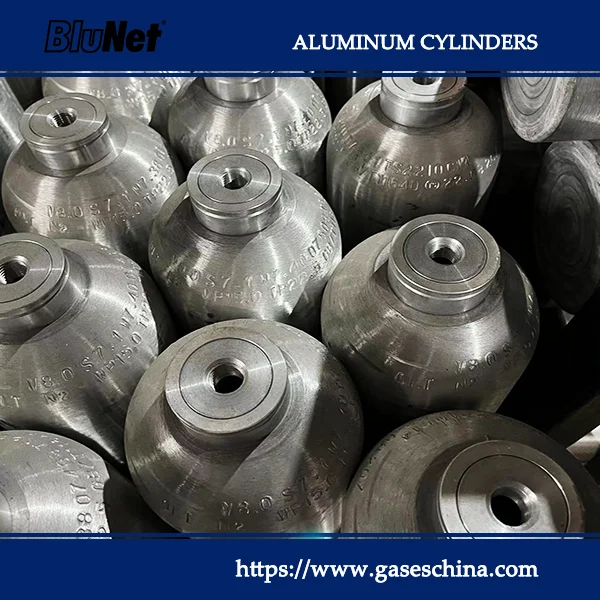

Aluminum Cylinders with TPED/DOT/GB

DSW Industry offers various aluminum cylinders for transporting and storing industrial gas, medical oxygen, food and beverage-grade gas, and alternative aerospace gases.

Compliance with global regulatory standards is critical for international trade. Aluminum cylinders with TPED, DOT, and GB certifications offer a reliable and compliant solution for businesses operating across borders.

Applications: Aluminium cylinders are also used to store ultra-high-purity gases for various applications, including electronics manufacturing, speciality and calibration gas, industrial gas, medical oxygen, food and beverage-grade CO2, SCUBA, fire and rescue operations, alternative fuel, and aerospace.

Aluminum Tanks Specification chart

| Type | Water Capacity (L) | Outer Diameter (mm) | Height (mm) | Weight (kg, without valve) | Working Pressure (MPa) | Design Wall Thickness (mm) |

|---|---|---|---|---|---|---|

| LW-60-0.5-20H | 0.5 | 60 | 285 | 3.1 | 0.6 | 200 |

| LW-75-0.7-15H | 0.7 | 75 | 295 | 4 | 0.9 | 150 |

| LW-82-0.7-15H | 0.7 | 82 | 235 | 4.2 | 0.9 | 150 |

| LW-89-1.0-15H | 1.0 | 89 | 269 | 4.5 | 1.2 | 150 |

| LW-89-1.4-15H | 1.4 | 89 | 345 | 4.5 | 1.4 | 150 |

| LW-108-1.0-15H | 1.0 | 108 | 210 | 5.5 | 1.3 | 150 |

| LW-108-1.4-15H | 1.4 | 108 | 264 | 5.5 | 1.6 | 150 |

| LW-108-2.0-15H | 2.0 | 108 | 346 | 5.5 | 2.1 | 150 |

| LW-108-2.5-15H | 2.5 | 108 | 413 | 5.5 | 2.5 | 150 |

| LW-120-2.0-15H | 2.0 | 120 | 320 | 6.1 | 2.7 | 150 |

| LW-120-2.5-15H | 2.5 | 120 | 369 | 6.1 | 3.0 | 150 |

| LW-120-2.8-15H | 2.8 | 120 | 398 | 6.1 | 3.2 | 150 |

| LW-120-3.2-15H | 3.2 | 120 | 437 | 6.1 | 3.5 | 150 |

| LW-140-4.0-15H | 4.0 | 140 | 420 | 7.1 | 4.2 | 150 |

| LW-140-5.0-15H | 5.0 | 140 | 500 | 7.1 | 4.9 | 150 |

| LW-140-6.0-15H | 6.0 | 140 | 580 | 7.1 | 5.6 | 150 |

| LW-140-8.0-15H | 8.0 | 140 | 741 | 7.1 | 7.2 | 150 |

| LW-140-5.0-20H | 5.0 | 140 | 525 | 9.3 | 6.3 | 200 |

| LW-140-6.0-20H | 6.0 | 140 | 652 | 9.3 | 7.98 | 200 |

| LW-159-10.0-15H | 10.0 | 159 | 730 | 8 | 8.8 | 150 |

| LW-184-9.0-20H | 9.0 | 184 | 575 | 12.2 | 12.0 | 200 |

| LW-184-10.0-20H | 10.0 | 184 | 620 | 12.2 | 12.9 | 200 |

| LW-184-11.0-20H | 11.0 | 184 | 665 | 12.2 | 14.2 | 200 |

| LW-184-12.0-20H | 12.0 | 184 | 710 | 12.2 | 15.4 | 200 |

TPED/DOT/GB Aluminum Gas Cylinders

Aluminum also has a lower chance of sparking, which makes it ideal for holding gas.

Because aluminum passes cylinder inspection so frequently, it’s less likely to rust, making it preferable to steel.

The three most significant advantages of aluminum’s numerous attractive qualities are its lightweightness, toughness, and corrosion resistance.

Any operation that handles gas cylinders may have to lift dozens or even hundreds of canisters simultaneously.

One of the most important factors is how easily the tanks can be transported and stored.

The cylinders are also under tremendous pressure; any break or puncture could result in a hazardous situation.

Aluminum is sturdy and long-lasting enough to endure accidental knocks and hits without significant harm.

Last but not least, the materials included in gas cylinders can be very toxic and harm the metal, especially over time.

Aluminum alloys provide exceptional corrosion resistance for the metal canisters, the metal valves, and other parts utilized with the cylinders.

The benefits of aluminum alloy application on gas cylinders

Aluminum alloys offer several advantages over steel for gas cylinders: lighter weight, improved corrosion protection, low-temperature resistance, and the potential to be recycled at end-of-life.

Good Heat Transfer

Aluminum alloy’s thermal conductivity is many times greater than that of steel. It is second only to copper in terms of thermal conductivity.

High Specific Strength

Compared to steel, aluminum has a higher specific strength and is a more common structural material.

Higher explicit-strength materials can result in lighter equipment for portable gas cylinders, reducing energy consumption and transport expenses.

Low-Temperature Resistance

The crystal structure of aluminium alloy is face-centred cubic.

Because the face-centered, cubic crystal structure exhibits a strong coordination ability, aluminum alloy gas cylinders are not prone to brittle cracks when used in shallow temperatures.

Furthermore, aluminium’s strength and lightness, along with its mechanical properties, remain unaffected. Aluminium alloy can resist low temperatures below -269°C without special requirements.

Manufacturing Processes of Aluminium Bottles

- Punching and Drawing: This is the primary method for producing seamless aluminium alloy gas cylinders. It involves heating an aluminium billet, punching it into a short, thick cup, and then drawing and closing it to form the final shape.

- Cold Extrusion: Cold extrusion creates seamless aluminium cylinders by pressing the billet at room temperature, followed by closure. While cost-effective and straightforward, this method requires high-tonnage presses.

- Deep Drawing: This process draws an aluminium plate into a long, cup-shaped form before sealing one end. Although it offers a consistent wall thickness, it has a low material utilisation rate and high production costs, making it less popular among manufacturers.

- Spinning: Spinning involves forming bottles from aluminium alloy plates. It allows for significant plastic deformation—over 70%—in a single session, eliminating the need for multiple drawing and annealing steps. This method is particularly suitable for small-batch production and complex shapes.

Applications Across Industries

- Medical Oxygen: Used in hospitals, ambulances, and home care, both portable and stationary.

- Specialty & Calibration Gases: Ideal for laboratories, calibration tasks, and electronic gas applications.

- SCUBA & Recreational Gases: Suitable for individual diving setups or portable refill stations.

- Fieldwork & Research: Provides a mobile gas supply for testing or temporary setups.

- Breathing Apparatus: Used in firefighting and SCBA equipment.

- Alternative Fuels: Small-scale demonstrations or equipment requiring portable gas supply.

- Beverage Gases: CO₂ supply for beer, soft drinks, and beverage dispensing systems.

Reviews

There are no reviews yet.