Key Features:

- Vacuum and Multi-layer Insulation for temperature control.

- Safety Features such as pressure relief valves and emergency venting.

- Material Properties optimized for low temperatures and corrosion resistance.

- Portability with flexible design options for stationary and portable storage.

- Gasification Capability to enable controlled evaporation.

- Compliance with industry regulations for safe operation and handling.

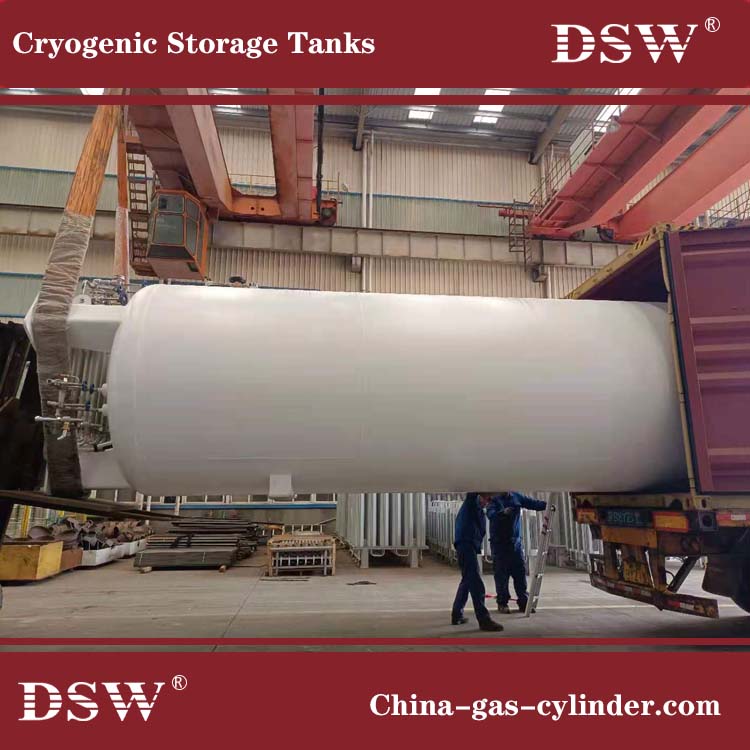

Cryogenic Liquid Tanks

The cryogenic liquid tanks for liquid nitrogen products are most popular in India, Pakistan, Vietnam, Indonesia, Brazil, Russia, Mexico, United States, Turkey, Germany, etc.

The cryogenic tank consists of two tanks Outer & Inner Tank. The inner tank is made out of stainless steel 304L (X5 CrNi 18-10) & design code EN13458, While the outer one is made of CARBON STEEL & design code EN13458.

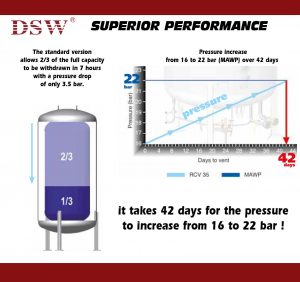

The gap between tanks is filled with Perlite aggregation and super insulation by vacuum technology.

Complete range of bulk cryogenic storage tanks and solutions delivering proven reliability, reduced maintenance, and lowest cost of ownership for the full spectrum of liquefied gases. Trailers, semi-trailers, swap bodies, liquid tube trailers and railcars for safe and efficient distribution of non-flammable and flammable liquid gases.

Main Applications:

- LNG (Liquefied Natural Gas): Used for energy transportation and storage.

- Oxygen, Nitrogen, and Argon Storage: Used in healthcare, metal fabrication, and electronics industries.

- Industrial and Laboratory Gases: Including gases for medical, food processing, and welding industries.

- Aerospace and Cryogenics: Cryogenic tanks are used to store fuels like liquid hydrogen or liquid oxygen for space exploration and propulsion systems.

Reviews

There are no reviews yet.